Products

-

Pipes

-

Bars

-

Tubes

-

Butt weld fittings

-

Flanges

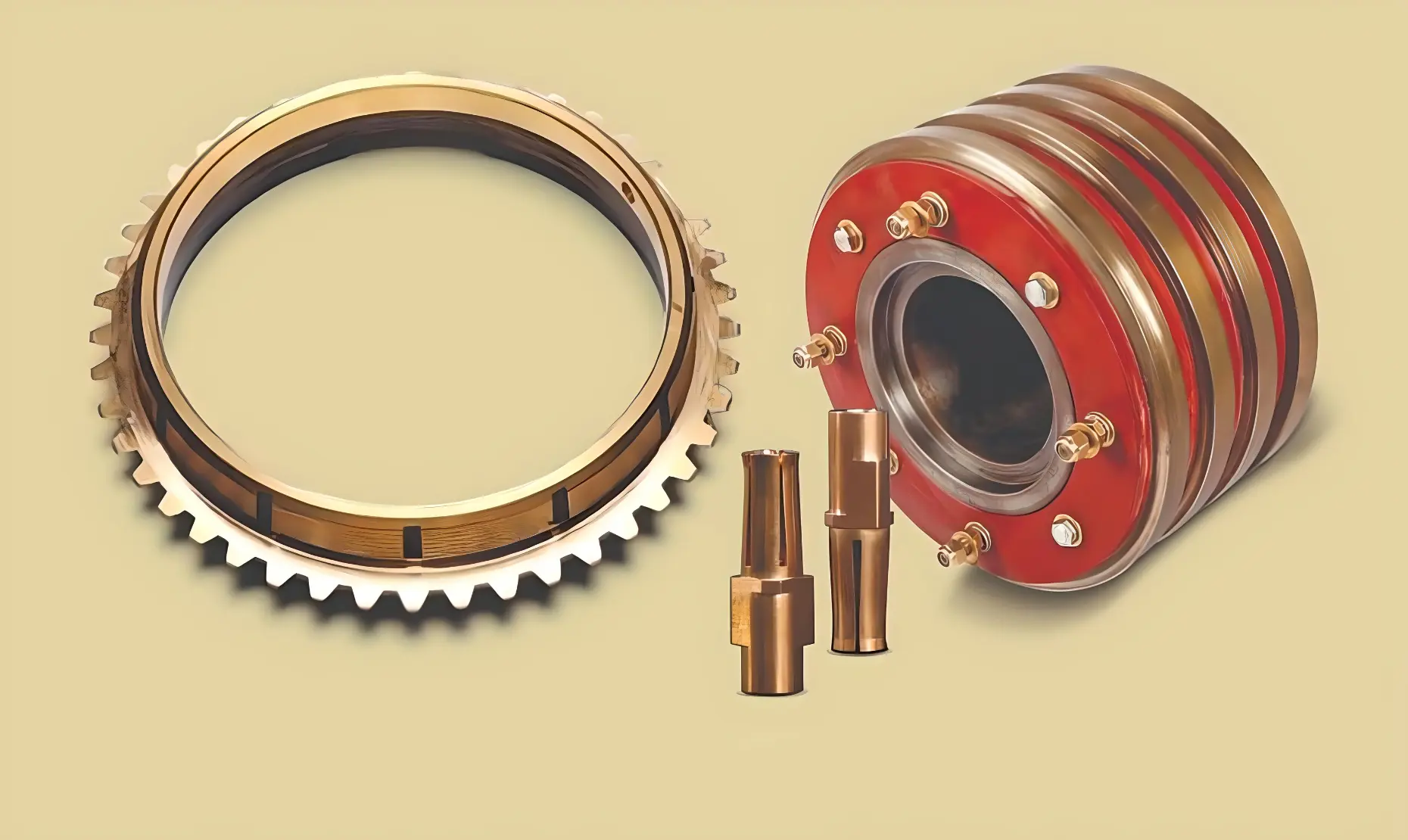

In the marine industry, the highest level of corrosion resistance is essential, and this is

achieved through the use of high-performance Cupro-Nickel alloys.

Our fully integrated production process encompasses every stage, from raw material sourcing to

processes such as

melting, casting, extrusion, drawing, forging, forming, stamping, and machining. This allows us

to manufacture a comprehensive range of pipes, tubes, and profiles that adhere to various

international standards or dedicated specifications for copper-nickel products. We specialize in

providing seamless pipes to meet the complete requirements of marine projects.

We are dedicated to constantly improving our service by maintaining large inventories of

finished products, and we are able to accommodate orders of either small or large quantities to

meet the needs of our customers. In addition to offering copper-nickel products for seawater

systems, we also provide aluminum bronzes and nickel-copper alloys suitable for specific

military applications.

Armind Machinery

Armind Machinery